pbolus

pBolus is used in radiation therapy where a patient requires full prescription dose on the skin surface. The pBolus acts as a tissue equivalent material, placed on the patient skin to account for the build-up region of the treatment beam. There are currently a variety of different Bolus materials in use throughout Australia including thermoplastic sheets, pellets and gel slabs (Superflab).

In general, the aim is that the pBolus will contact well with the patient’s skin resulting in minimal air gaps, be of uniform density and thickness, be reproducible to position and not cause discomfort to the patient in either the creation or daily positioning of the pBolus.

Literature reports that 3D printing allows the fabrication of tissue equivalent pBolus of detailed volumetric structures defined on the CT image data. This results in the possibility for pBolus to be made for complex shapes fitting closely to the patient’s skin in a reproducible fashion.

Patient Customised pBolus

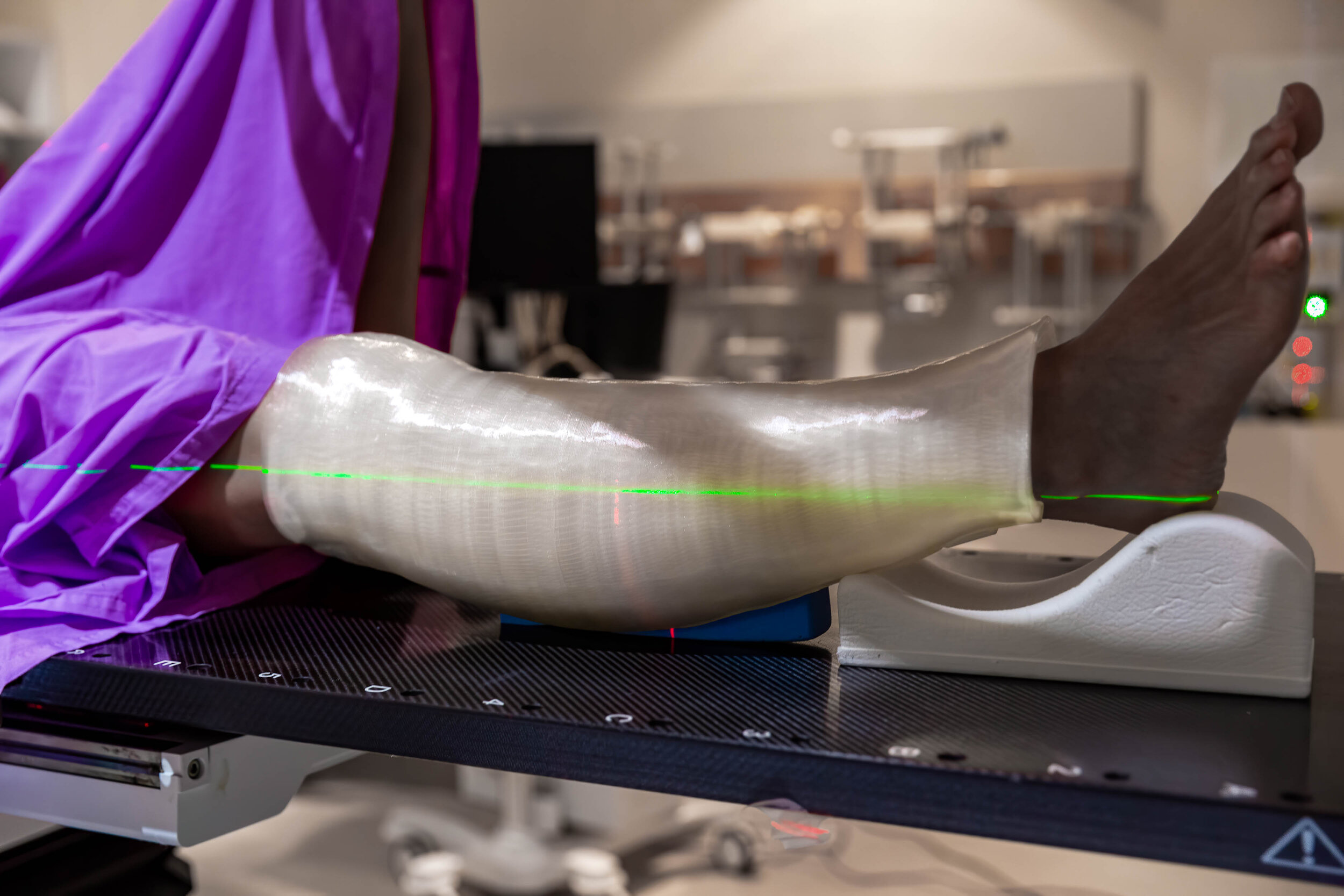

Utilising advanced 3D design and 3D Printing innovations, 3D One has been able to develop a streamlined, additive manufacturing process that takes an accurate map of a patient’s required radiation therapy treatment area to create a customised pBolus which facilitates delivery of optimal skin dose, minimising the risk to healthy tissues.

The 3D One pBolus is designed from a patient’s CT scan and created in a flexible thermoplastic urethane (TPU). High spatial accuracy is achieved without air gaps, being significantly superior to proprietary alternatives. The TPU attenuates similarly to water, confirmed via a Planning CT.

3D One has implemented a manufacturing process capable of a high degree of accuracy, to produce on demand custom, pBolus for individualised patient treatment.

Why use pBolus?

Designed directly from CT or 3D Optical scans for a customised fit:

The pBolus is precisely printed, shaped to reflect the exact treatment area of each patient.

Minimal air gaps with uniform density and thickness:

The pBolus fits more precisely than conventional bolus material.

Automated process for fast turnaround on demand:

Design and print is streamlined for fast, highly accurate production and delivery to your medical clinic.

Comfortable patient experience:

Creating the pBolus, and using it, will not cause discomfort to the patient.

Reclaimable and able to be sanitised:

Safe and non-toxic, the pBolus can be sanitised for future use.

pBolus based on complex shapes from CT data

The pBolus is placed on the patient’s skin to function as a tissue-equivalent material, accounting for the build-up region of the treatment beam.

A variety of materials are used in Australia to create radiation Bolus’. These include thermoplastic sheets and pellets, gel slabs, dental wax and wet combine.

The pBolus is tailored to specific applications, taking advantage of 3D printing technology, which allows precise and accurate manufacturing that considers the detailed volumetric structures shown on CT images.

Created to exact specifications

The pBolus is a 3D printed, proprietary thermoplastic urethane (TPU) product that attenuates similarly to water.

It is designed using patient CT scans, then produced with a streamlined, additive manufacturing process.